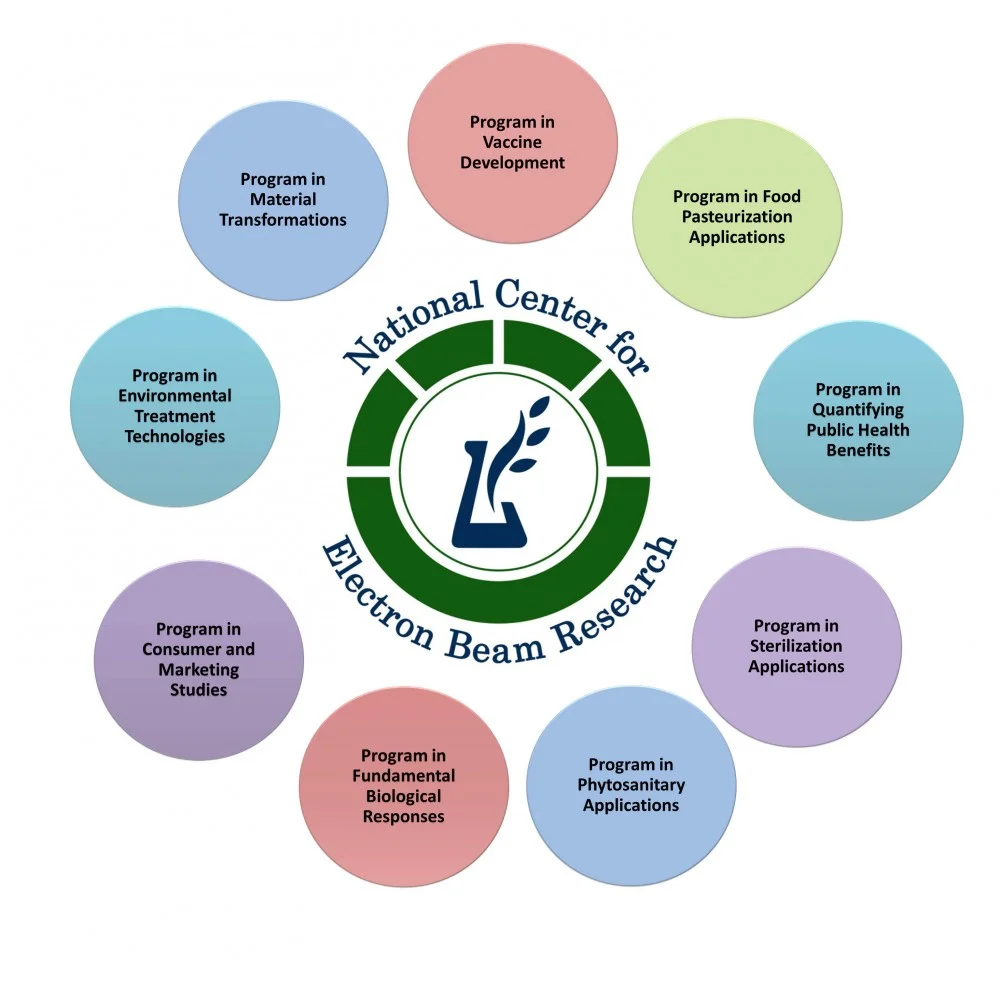

Research Programs

Researchers from across Texas A&M University System and the outside (namely private industry, academia and government) partner to develop research projects in each of the different program areas. Both fundamental and translational research projects are pursued.

The ultimate goal of these projects is to develop new information, new processes and new approaches that will ultimately enhance the quality of life of humans around the globe.

eBeam and X-ray Irradiation Facilities

The activities of the Center hinge around of the world’s largest, high throughput research/ commercial level E-beam and X-ray irradiation equipment. The eBeam and X-ray irradiation equipment is housed in a 16,000 sq. feet dual modality (eBeam and X-ray) facility on campus that has 2 vertically mounted 10MeV, 15 kilowatt eBeam Varian linear accelerators and one horizontally mounted 5MeV, 18 Kilowatt X-ray Varian linear accelerator. The facility utilizes a single conveyance system to move the product in and out of the process chamber. All LINACs and conveyers are controlled with Allen Bradley Programmable Logic Control (PLC) software. This software, along with SureBeam’s RS View Human Interface software, enables the electronic pasteurization process to be virtually automated and very tightly controlled with few staffing requirements. There is a state of the art dosimetry lab equipped with alanine-based dosimetry system that includes a Bruker e-scan EPR work station. The dosimetry system is NIST- traceable. The facility and the dosimetry system has been reviewed by the USDA-FSIS to meet the required QA/QC system to support commercial food irradiation.

In addition to the high energy eBeam and X-ray facilities, the eBeam Center works closely with the TAMU Nuclear Science Department’s Nuclear Science Center and the Cyclotron Institute. There is a lanthanum source (La2O3) when irradiated in the reactor, gets activated to make La-140 which has a key gamma energy of 1.59 MeV. It has a half life of 1.678 d. Additionally, there are there are X-ray sources at 100 kVp and 250 kVp.

The irradiation facilities at Texas A&M University provide an unparalleled array of high energy and low energy eBeam and X-ray sources that permit a wide variety of studies allowing fundamental science questions to be pursued to commercial-viable translational research.

Vaccine Development

The Center is partnering with private industry, government and academic researchers to develop the next generation of animal and human vaccines using eBeam and X-ray technologies. Vaccines against a variety of bacterial, viral and protozoan agents are currently under development.

Pasteurization, Sterilization and Phytosanitary Applications

The Center is heavily invested in projects that are designed to enhance food safety, protect against the importation of invasive insects and pests and to develop new processes to sterilize medical devices and products. eBeam and X-ray technologies that can be customized to different foods, different agricultural products (eg cut-flowers, crops) and medical devices are under development. Recently in partnership with the International Atomic Energy Agency (IAEA), hospital food caterers, a pediatric oncologist, and about a dozen international groups, the Center has embarked on an ambitious project to develop and test a series of eBeam pasteurized foods designed for hospital patients. The first set of foods is targeted for pediatric cancer patients.

Quantifying Public Health Benefits

In collaboration with the University of Texas School of Public Health we employ advanced Quantitative Microbial Risk Assessment (QMRA) approaches to communicate the economic and public health benefits of employing food irradiation. These are powerful decision making tools that are of significant value to the food industry and regulatory agencies. Quantifying the public health benefits is a cornerstone of communicating and managing science-based risks.

Fundamental Biological Responses

Researchers are interested in gaining a better insight into how microorganisms respond to E-Beam, Gamma and X-ray radiation of different energies, different dose-rates. The availability of multiple sources of ionizing radiation coupled with a standard calibrated dosimetry system allows for studies that were previously hard to accomplish. Advanced microbiology, genomic and proteomic approaches are involved in these studies.

Consumer, Economic and Marketing Studies

The consumer acceptance of eBeam pasteurized foods, the consumers’ willingness to purchase E-Beam pasteurized foods and the food industry’s ability to market eBeam pasteurized foods are key hurdles that stand in the way of widespread availability of E-Beam or X-ray pasteurized foods. Study after study and actual retail sales demonstrate that consumers are willing to pay a premium for food safety. Yet, today, consumers have no choice in the market place in terms of irradiated foods. The availability of irradiated foods in the retail market place is highly limited due to poor understanding of the consumer needs, economic drivers and an appropriate marketing plan. The Center is working to improve the marketability, economics, and consumer acceptance of irradiated foods.

Environment Treatment Technologies

The focus of activities is to harness eBeam and X-ray technologies to treat municipal drinking and wastewater, and industrial waste streams. Projects underway are focused on disinfecting against microbial pathogens, destroying estrogenic compounds, chlorinated compounds and other recalcitrant pollutants. Researchers with expertise in microbiology, chemical engineering and process chemistry are involved. The projects are funded from both federal and private sources.

Material Transformations

Research is well underway to enhance the material characteristics of different natural and man-made materials. Projects include the functionalizing of artificial tissues, material modifications and material enhancements.